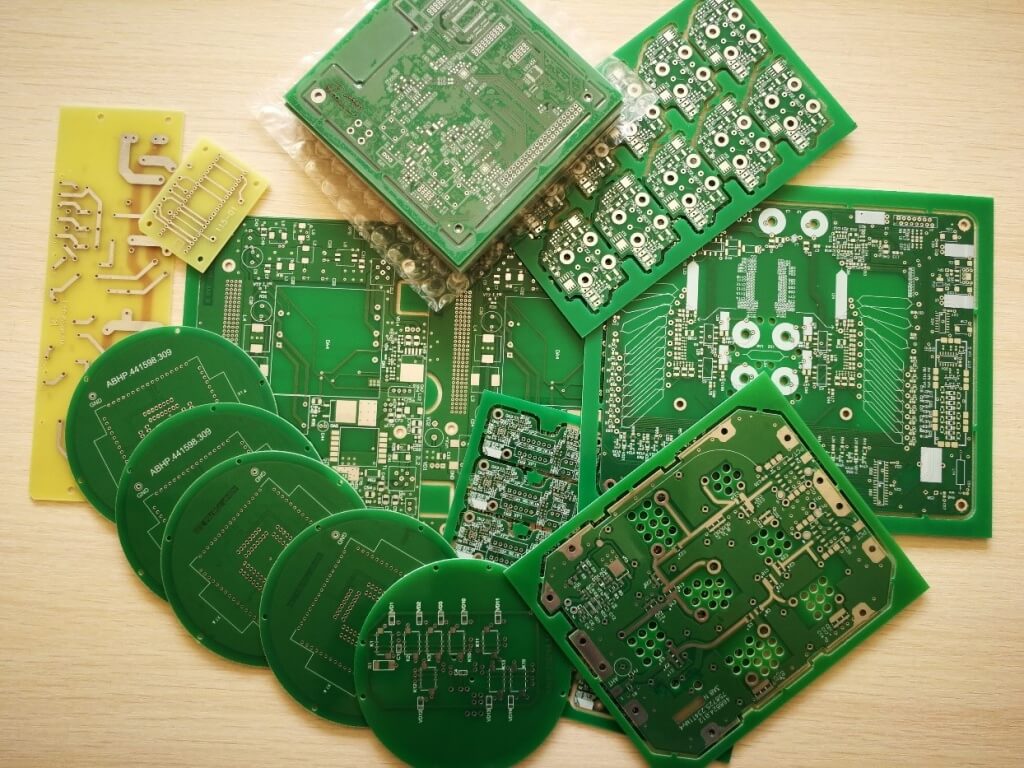

Manufacturing of printed-circuit boards

Description

Open Joint Stock Company “AGAT-Control Systems” – Managing Company of “Geoinformation Control Systems” Holding manufactures single- and double-sided printed-circuit boards by means of subtractive process (mainly in small batches).

Technical characteristics

| Minimum conductor width, mm | 0.25 |

| Minimum distance between edges of conductive pattern elements, mm | 0.15 |

| Minimum diameter of plated holes, mm | 0.3 |

| Warranty belt, mm | 0.05 |

| Maximum board size, mm | 400 х 500 |

| Material | fiber-glass plastic (FR4 grade) |

| Copper foil thickness, mcm | 35 (18, 50) |

| Coating of conductive pattern elements: | – electroplating tin – lead with infrared melting – hot tin-plating – lead alloy with hot air equalization |

| Coating of edge board contacts | Н6 |

| Soldering mask: | liquid photoformed; colours: green, black, white |

| Marking | by screen-printing technique; colours: black, white |

| Contouring: | - milling (CNC), - punching, - machining |

| Group blank plate can be supplied. Minimum group blank plate, mm | 160х110 |

| Quality control | acc. to GOST 23752-79 and customer’s design documentation |

| Periodic testing | for 3-grade stiffness |

| Time of manufacture | 2 to 4 weeks |

Printed-circuit boards are manufactured with the help of a laser image generator ЭМ5039.

The cost of manufacturing is determined for each order taking into account the actual costs of PCB manufacturing, including technological preparation of production (production of photographic templates and programs for CNC machines). Production preparation costs are not included in the re-manufacturing of printed circuit boards.

Production facilities

- Phone: +375 (17) 287-12-45

- E-mail: market@agat.by